In the world of sailing, every component plays a crucial role in the performance and efficiency of the boat.

When it comes to sailing blocks, the choice between caged and non-caged ball bearings can significantly impact the overall sailing experience and performance. In this post, we will explore the performance difference between caged ball bearings and non-caged ball bearings, specifically when used in sailing blocks. By understanding the advantages of caged ball bearings, sailors can optimise their rigging systems for smoother sailing and improved control.

Reduced Friction for Effortless Trimming

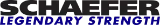

One of the primary advantages of caged ball bearings in sailing blocks is their ability to minimise friction. The carefully designed cage that separates the balls ensures smooth rolling motion with minimal contact and frictional resistance. This translates into lighter and more responsive control, allowing sailors to make precise adjustments on the control lines and sheets with less effort.

Enhanced Durability and Reliability

Sailing blocks are subjected to high loads and constant exposure to harsh marine environments. Caged ball bearings excel in such conditions, offering enhanced durability and reliability. The cage helps maintain proper ball alignment, preventing the balls from rubbing against each other, and reducing wear. This ensures consistent performance over extended periods, even in challenging sailing conditions.

Optimal Load Distribution and Stability

Caged ball bearings ensure optimal load distribution, enhancing stability and control. The cage keeps the balls evenly spaced, preventing skewing or jamming under heavy loads. This uniform load distribution minimizes stress concentrations, reducing the risk of premature wear or failure. With improved stability and load-bearing capacity, caged ball bearings enable sailors to handle higher loads with greater control, enhancing the overall performance of the rigging system.

Smooth Sailing in High-Speed Scenarios

High-performance sailing often involves high-speed manoeuvres, where responsiveness and precision are vital. Caged ball bearings excel in such scenarios, allowing for smoother and more efficient rotation even at elevated speeds. The cage prevents the balls from colliding during rapid movements, minimizing heat generation and reducing the risk of binding. This enables sailors to execute quick and precise adjustments, ensuring optimal sail trim and maximizing the performance of their boat.

Advantages of a non-caged ball bearing block

With all that said above, why would you want a non-caged ball-bearing pulley? Non-caged ball-bearing blocks are less expensive compared to caged-bearing pulleys. This is because there are fewer components needed and assembly is much quicker and easier.

Smaller sheaves may not have enough room to include a cage for the ball bearings, and typically even non-caged ball bearings have less rolling friction than a plain bearing pulley.

The load capacity of a pulley is primarily determined by the design and quality of the bearings used, rather than whether the bearings are caged or non-caged. Both caged and non-caged ball bearings can be designed to handle various working loads, and the load capacity will depend on factors such as the size, material, and construction of the bearings.

Summary

When it comes to sailing blocks, the choice of ball bearings can significantly impact sailing performance and control. Caged ball bearings offer distinct advantages over non-caged alternatives, providing reduced friction, enhanced durability, optimal load distribution, and smooth operation even at high speeds. Sailors who prioritise these advantages in their rigging systems can expect effortless manoeuvring, improved responsiveness, and increased reliability on the water.

So, now you know the difference between caged and non-caged ball bearings, it’s worth noting how we manufacture and assemble our various block ranges.

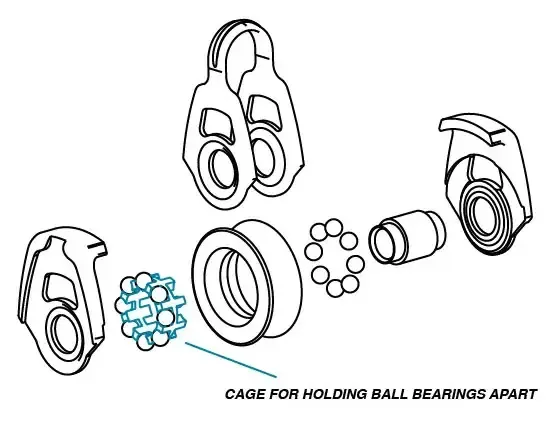

All of our dynamic blocks feature a caged ball-bearing system, with the exception of the 20mm dynamic block range. This is due to the size of the sheave and ease of assembly. The 60mm High Roller range also features caged roller bearings.

XHL blocks do not feature a caged ball-bearing system. This is due to the special design of the XHL bearing – a combination of both dynamic bearing technology and plain bearing technology.

See how we manufacture and assemble one of our caged ball-bearing blocks in the following video. Skip to 4:40 to see the bearings and cage being assembled.